I. Product Overview

Our company is an enterprise specializing in manufacturing spiral plate heat exchangers. We have a large-scale special plane for rolling spiral plate heat exchangers, with advanced manufacturing technology and rich experience, so as to ensure reliable poor quality.

Spiral plate heat exchanger is widely used in petrochemical industry, food, pharmacy, machinery, heat supply and waste liquid heat recovery, etc. Typical applications are alcohol processing and rich and poor oil processing in coking enterprises.

Compared with other types of heat exchangers, spiral plate heat exchangers are characterized by long heat transfer channels, large spacing between channels, high heat resistance and low leakage. Therefore, it has high heat exchange efficiency, and the temperature of the cold medium after heat exchange is easy to approach that of the hot medium. It is suitable for heating or cooling viscous materials and materials containing particles, but it is not suitable for heat exchange of materials containing fibers. Spiral plate heat exchanger is also suitable for condensation processing of organic compound steam.

Second, the basic structure and working principle of spiral plate heat exchanger

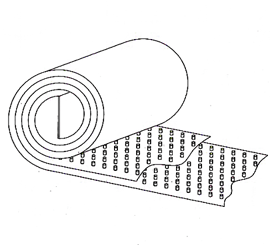

Spiral plate heat exchanger is made of two long steel plates stacked and rolled together. As shown in Figure 1, each plate is uniformly welded with distance columns, which make a certain distance between the two plates to form a heat exchange channel. The distance columns play a role in supporting the steel plates to resist fluid pressure, and also play a role in increasing turbulence when fluid flows in the heat exchange channel to improve heat exchange efficiency. The two fluids flowing through two adjacent channels have different temperatures, and they transfer heat through spiral steel plates to achieve the purpose of heat exchange. The distance between the two runners can be the same or different. The channel spacing should not be too small or too large. Too small is easy to block, too large is not conducive to heat transfer, and it is difficult to realize in the manufacturing process structure. Generally, 8-30mm is more suitable.

Figure 1

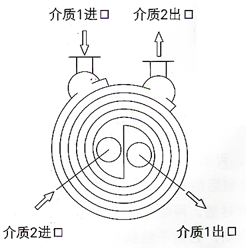

For the two media for heat exchange, if they are both liquids, they flow in the spiral direction in the six channels of the spiral plate heat exchanger, as shown in Figure 2, and they flow in countercurrent. The so-called countercurrent means that the two liquids flow in opposite directions in the adjacent channels, so that the two fluids can always keep a certain temperature difference in the process of mutual heat transfer, thus achieving better results.

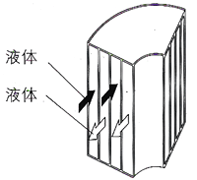

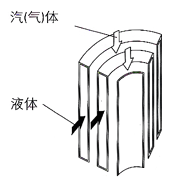

For the two media of heat exchange, one is liquid, and the other is vapor (gas), which can flow in a cross-flow manner. The so-called cross-flow means that the liquid flows in a spiral direction, and the vapor (gas) directly passes through the axial direction of the heat exchanger, as shown in Figure 3. This is mainly due to the characteristics of vapor (gas), which is suitable for larger flow, reduced resistance and suitable for organic vapor condensation. According to the specific working conditions, steam can also flow in the spiral direction, but the gas usually passes directly in the axial direction because of its small heat capacity.

Figure 2, Figure 3

Three, the type of spiral plate heat exchanger

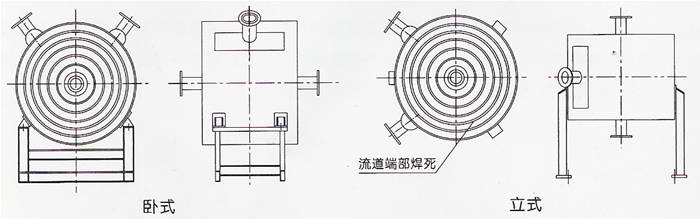

1. Non-detachable

After rolling, the spiral plate heat exchanger is welded to death at both ends, so it can't be disassembled to form a fixed structure, and the inside of the process can't be touched. It is suitable for fluid heat exchange which is not easy to block. Non-detachable, horizontal and vertical structures.

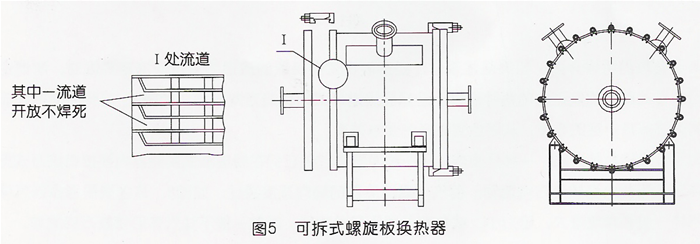

2. Detachable

After the spiral plate heat exchanger is rolled, only one runner is welded to death at each end, while the other runner is open, and then an end cover is added on the end face to seal it. The end cover can be disassembled to clean the inside of the flow channel. It is suitable for heat exchange of easily blocked fluids.

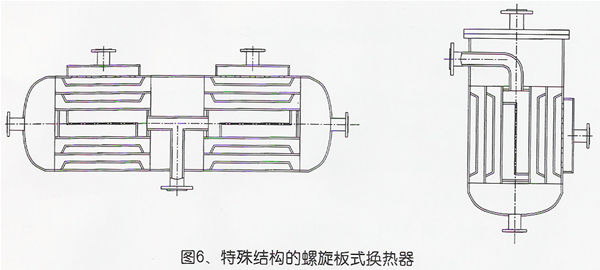

3. Special forms

Some spiral plate heat exchangers used in chemical industry need special structures, such as, according to the requirements of processing technology. Two ends are provided with heads and end covers, or two heat exchangers are connected together in series. The structures are different, which requires special design by the design department.

The main heat exchange materials of spiral plate heat exchanger are mainly divided into carbon steel and stainless steel. The spiral plate material of carbon steel is Q235A, and the spiral plate materials of stainless steel are 0Cr19Ni9(SUS304) and 00Cr17Ni4Mo2(SUS316L).

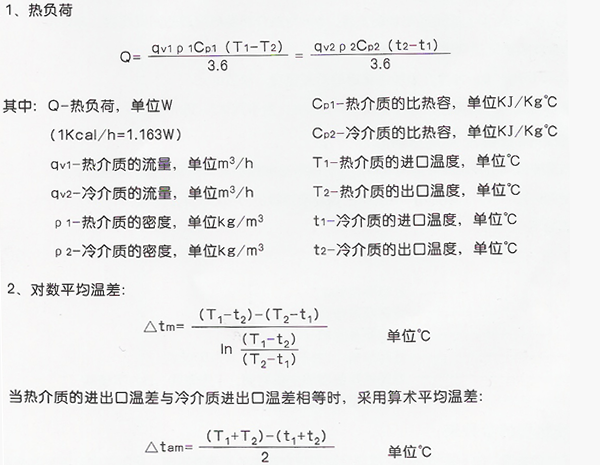

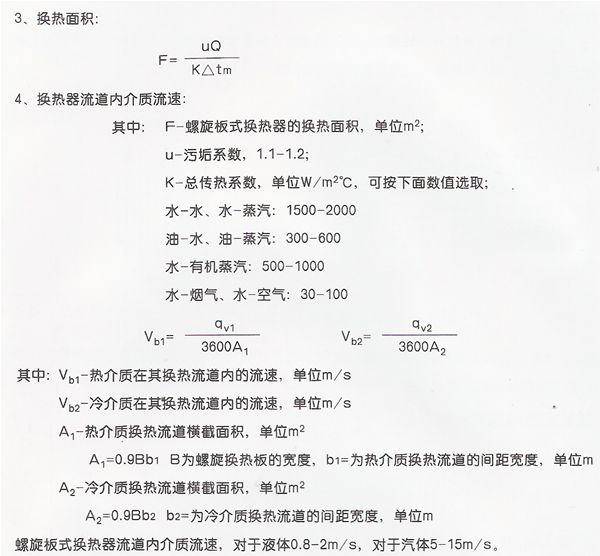

IV. Selection calculation of spiral plate heat exchanger

五、螺旋板式換熱器性能極其型號的表示方法

螺旋板式換熱器的最高工作溫度可達構成換熱器材料所能耐用的最高指標,最高可達300攝氏度。設計壓力可分為0.6、1.0、1.6MPa,相應地,針對碳鋼板而言螺旋換熱板的厚度應為4、5、6mm。

VI. Parameter Table of Spiral Plate Heat Exchanger

VII. Installation, Use and Maintenance of Spiral Plate Heat Exchanger

1. Installation: The spiral plate heat exchanger shall be installed and connected according to the design drawing. The foundation shall be a specially designed concrete foundation with high strength. Sufficient space should be left around for use and maintenance, and a floor drain should be provided underground.

2. Use: Do not exceed the designed pressure and temperature during use. Before operation, clean water should be used to flush the heat exchanger channel. A filter should be installed before the liquid medium inlet to prevent fibrous substances from entering the heat exchanger, so as to avoid blocking the heat exchange channel.

3. Maintenance: Check regularly in daily use, and clean up the residual substances in the flow channel in time after stopping use. If scaling or blockage occurs in the heat exchange runner, it can be cleaned by steam purging, or by chemical alkali solution or acid solution according to the scaling composition.